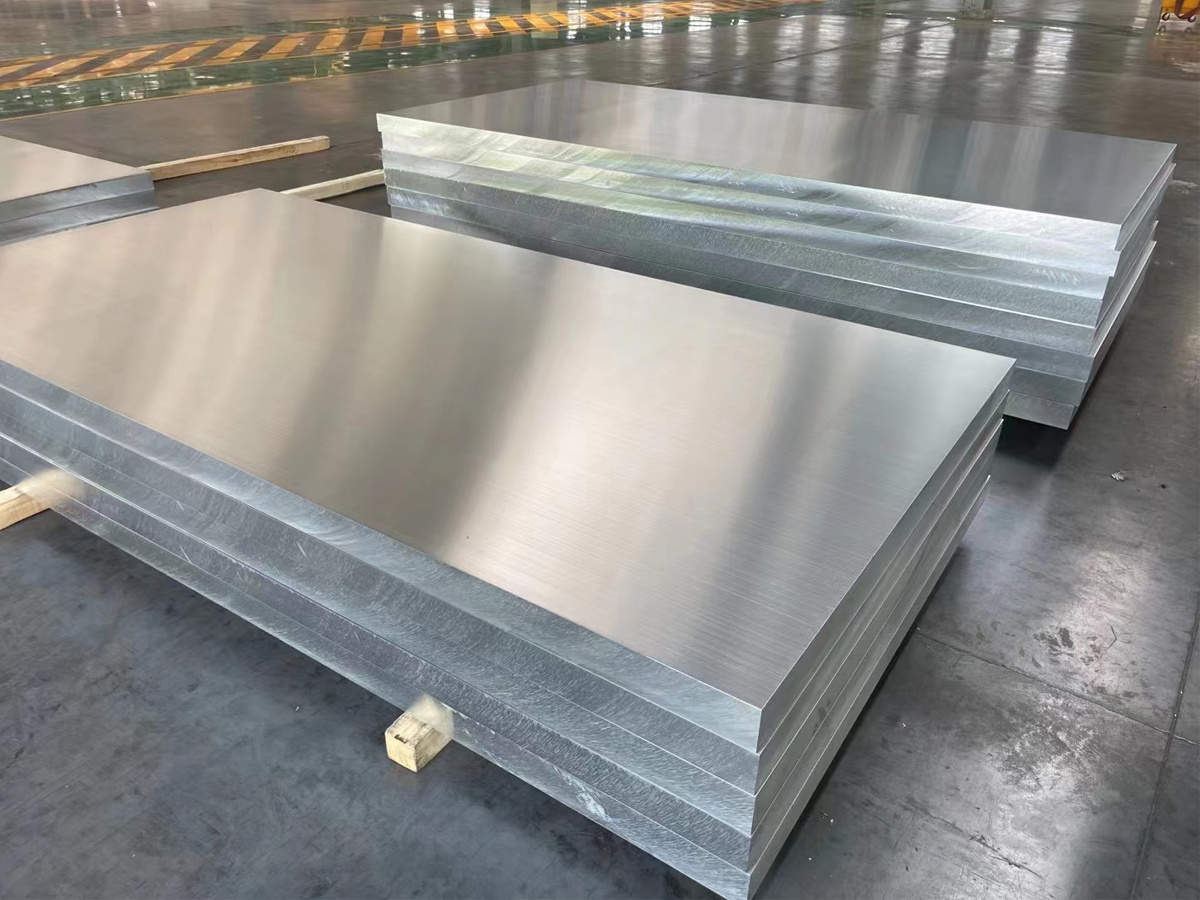

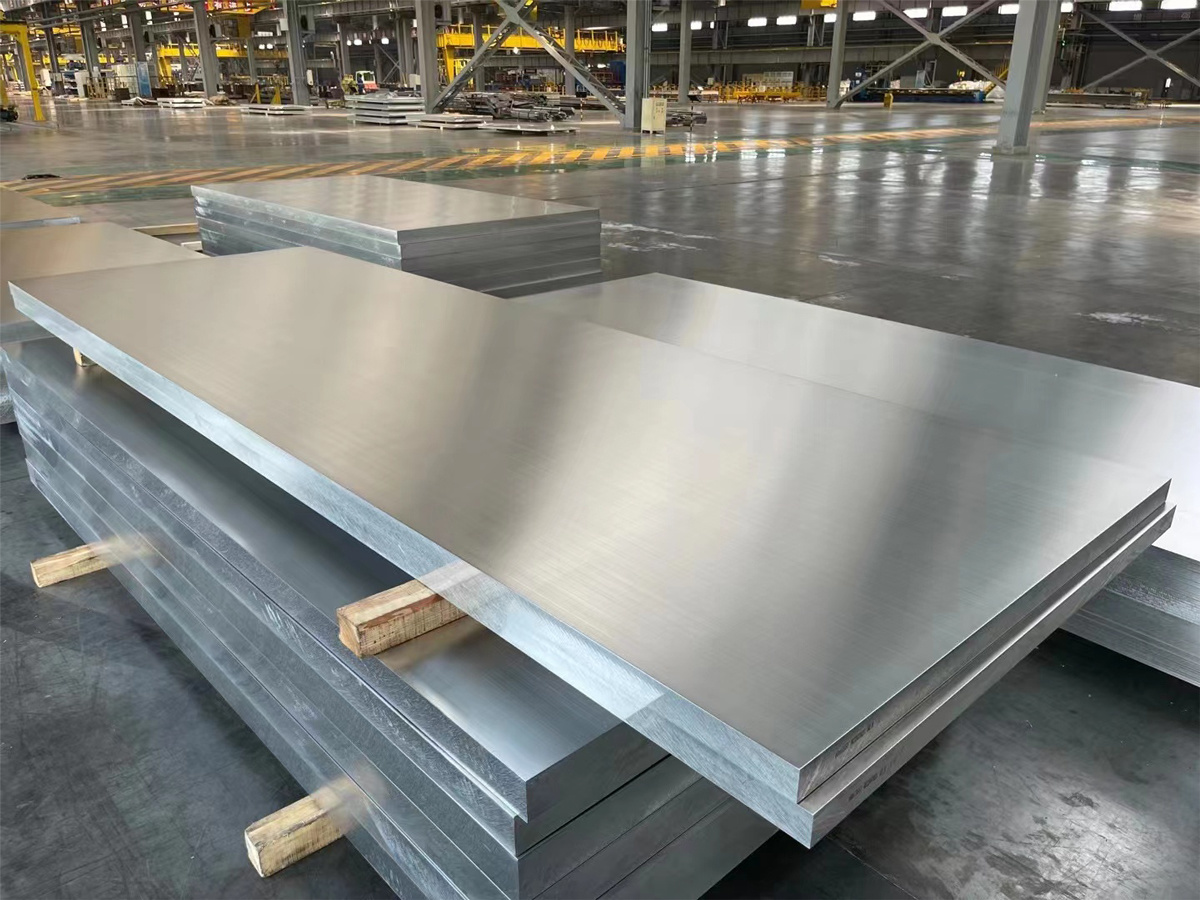

7075 T651 Aluminium Plate: The Ultimate High-Strength Solution for Demanding Applications

08-20

When it comes to high-performance materials, 7075 T651 aluminium plate stands out as a top choice in industries that require superior strength, durability, and reliability. As one of the strongest aluminium alloys available, 7075 aluminium plates have become a cornerstone in sectors such as aerospace, automotive, and defense, where performance is non-negotiable.

1. Understanding 7075 T651 Aluminium

The 7075 aluminium alloy is renowned for its exceptional mechanical properties. The 7075 T651 aluminium variant, in particular, undergoes a specific tempering process that enhances its characteristics. The T651 temper involves stress relief after solution heat treatment, which minimizes distortion during machining and improves the material’s overall stability.

7075 T651 aluminium is favored for its impressive hardness and high fatigue resistance, making it an ideal material for components subjected to high-stress environments. This alloy offers an excellent balance between strength and weight, which is why it's extensively used in the manufacturing of aircraft structures, automotive parts, and high-end engineering applications.

2. Key Properties of 7075 T651 Aluminium Plate

- High Strength-to-Weight Ratio: 7075 T651 aluminium plate is one of the highest strength aluminium alloys, making it perfect for applications that require lightweight yet robust materials.

- Impressive Hardness: The 7075 T651 hardness is one of its standout features, providing exceptional wear resistance and durability in challenging environments.

- Corrosion Resistance: While not as corrosion-resistant as other aluminium alloys, 7075 aluminium offers sufficient protection, especially when treated or coated, making it suitable for various demanding applications.

- Machinability: 7075 T651 plate and 7075 T6511 plate are known for their excellent machinability. The T651 temper ensures minimal residual stress, allowing for precise and efficient machining operations.

3. Applications of 7075 T651 Aluminium Plate

- Aerospace Components: 7075 aluminium plate is widely used in the aerospace industry, particularly for critical structural parts that demand high strength and low weight.

- Automotive Industry: In high-performance vehicles, 7075 T651 aluminium plates are used for suspension components, chassis parts, and other key elements where strength and weight are crucial.

- Defense Equipment: The defense sector relies on 7075 T651 for manufacturing robust and durable components that can withstand extreme conditions.

4. 7075 T651 vs. Other Aluminium Alloys

When comparing 7075 T651 with other aluminium alloys such as 6061 or 2024, the superior strength and hardness of 7075 T6511 become evident. While 6061 is more corrosion-resistant and easier to weld, 7075 aluminium is the go-to for applications where strength is paramount. 7075 T651 aluminium properties make it the preferred choice when failure is not an option.

5. Conclusion

The 7075 T651 aluminium plate is a material that engineers and manufacturers trust for its high strength, durability, and performance in the most challenging applications. Whether you’re looking for 7075 T6511 material properties for aerospace, automotive, or defense, this alloy delivers consistent and reliable results.

For more information on our range of 7075 aluminium plates or to discuss your specific requirements, contact us today. Let us help you find the perfect solution for your next project.